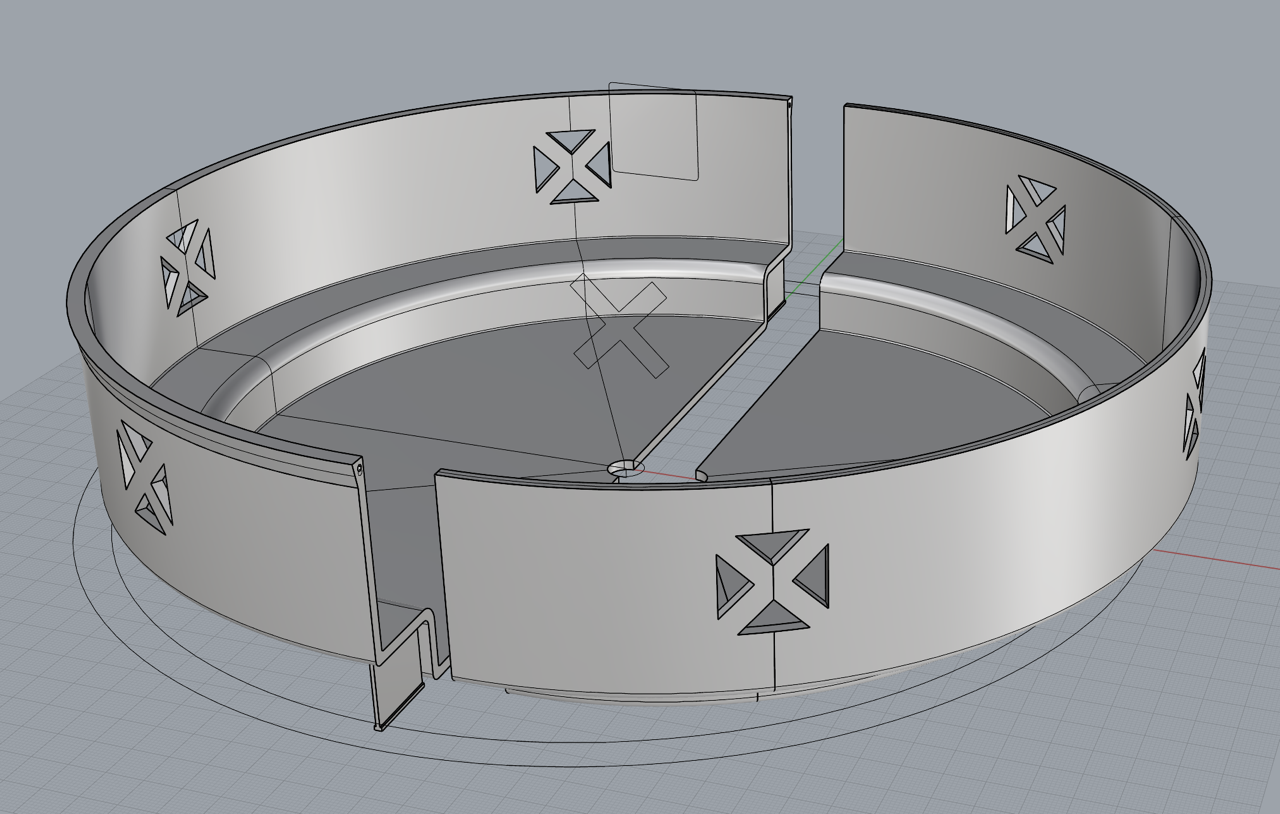

The original part was measured and replicated in CAD. The design was modified to make it printable and strong. Printed plastic parts have to be thicker than metal parts.

The parts were printed in ASA which allows for them to withstand outdoor heat and cold as well as sunlight. The parts were glued together with steel pins and braced on the inside. The parts were sanded and the gaps were filled with an outdoor polyester filler. Finally the parts were painted by the client with automotive paint.

Time for 4 models: 1.5 weeks

Uber Precise Parts

A second light lens was also produced using the same process. It used printed inserts to create the black X's.